Custom non-standard Precision Machining Teeth Helical Gear Rack Set Guide Rail rack-and-pinion

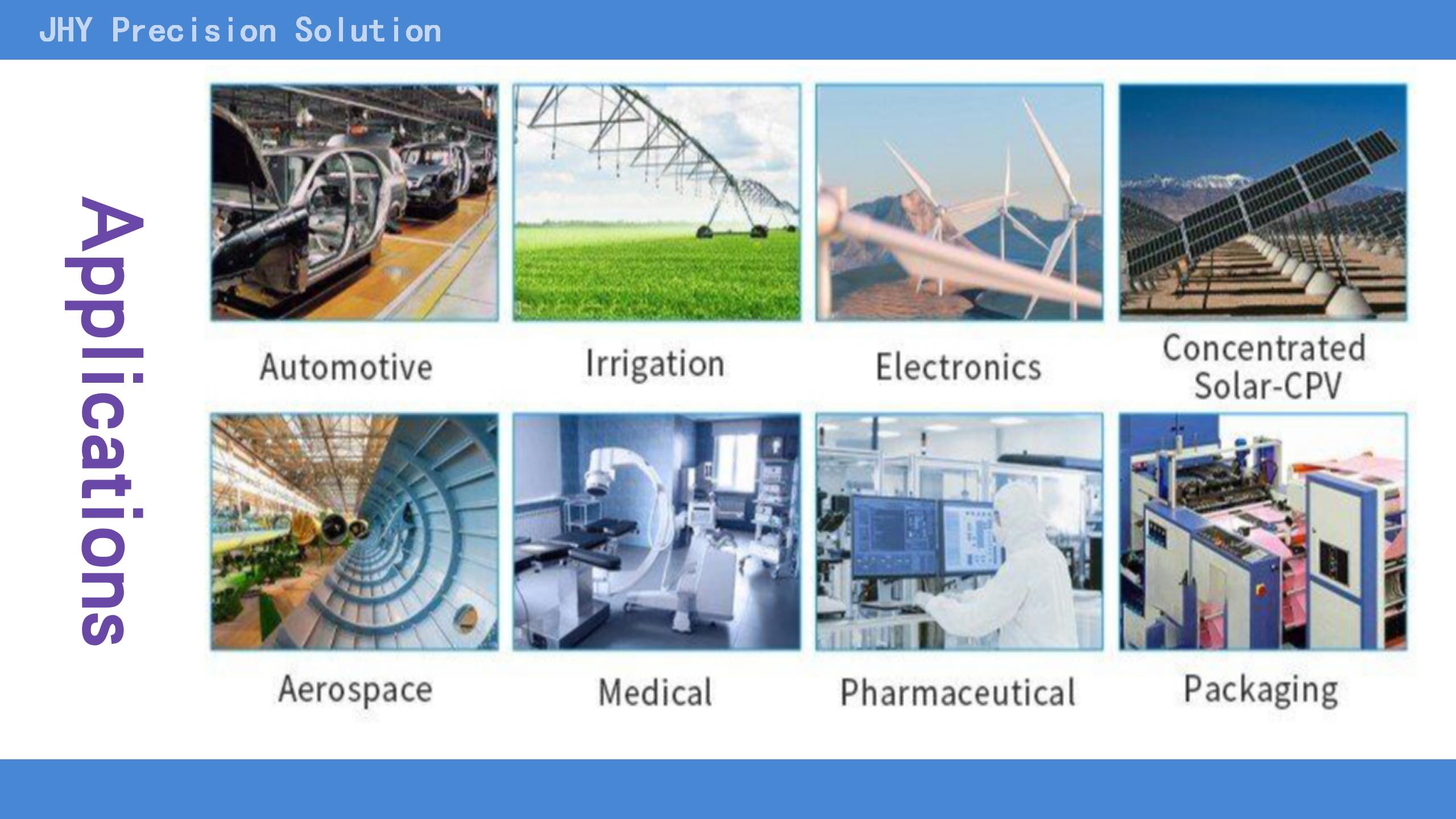

Shenzhen JHY Technology Co., Ltd is a steadily growing company which founded in 2011. As a world class custom manufacturing company, we specialized in precision CNC machining and aim to provide customers with high quality and reliable products.

We have rich experience in processing various materials, like SUS304,AL6061,FR4,S136,S440,POM and so on .We have advanced CNC milling equipment,Automatic lathe,Test equipment and other auxiliary equipment, which can provide CNC Turning, CNC Milling, Sheet Metal Machining Stamping, and also die casting and injection molding services to ensure our clients receive a professional and personalized service from first contact to final delivery.

We have formed complete manufacturing chain , as long as you give us the designs, functionality, performance, or even the idea of the product, our one-stop service can make product from the idea to reality.

Surface treatment

Anodize, Bead blasted, Silk Screen, PVD Plating, Zinc/Nickl /Chrome/Titanium Plating, Brushing,Painting, Powder Coated, Passivation, Electrophoresis, Conversion coating, Electro Polishing, Knurl, Laser/Etch/Engrave etc.

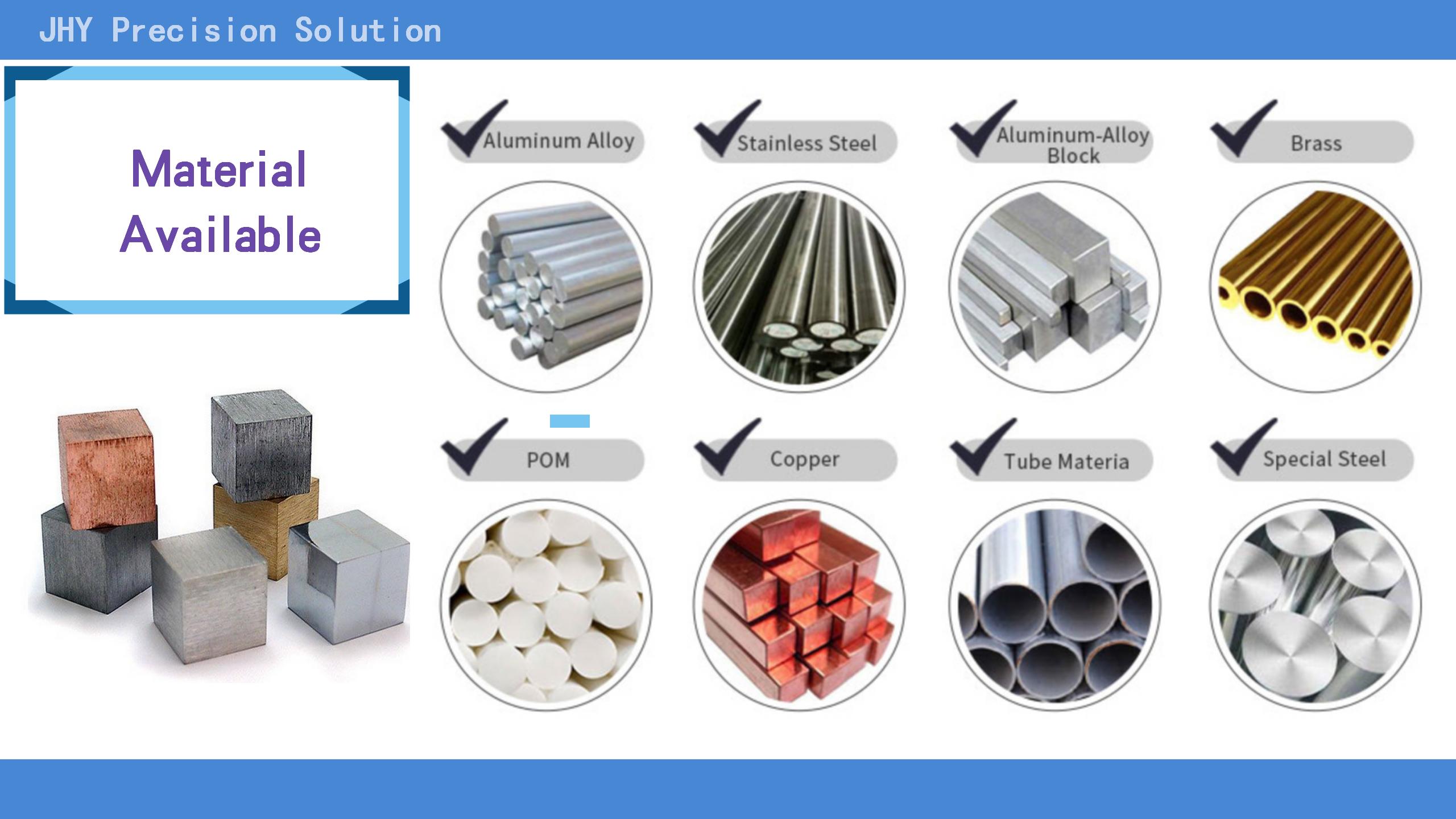

Machining materials are as below...

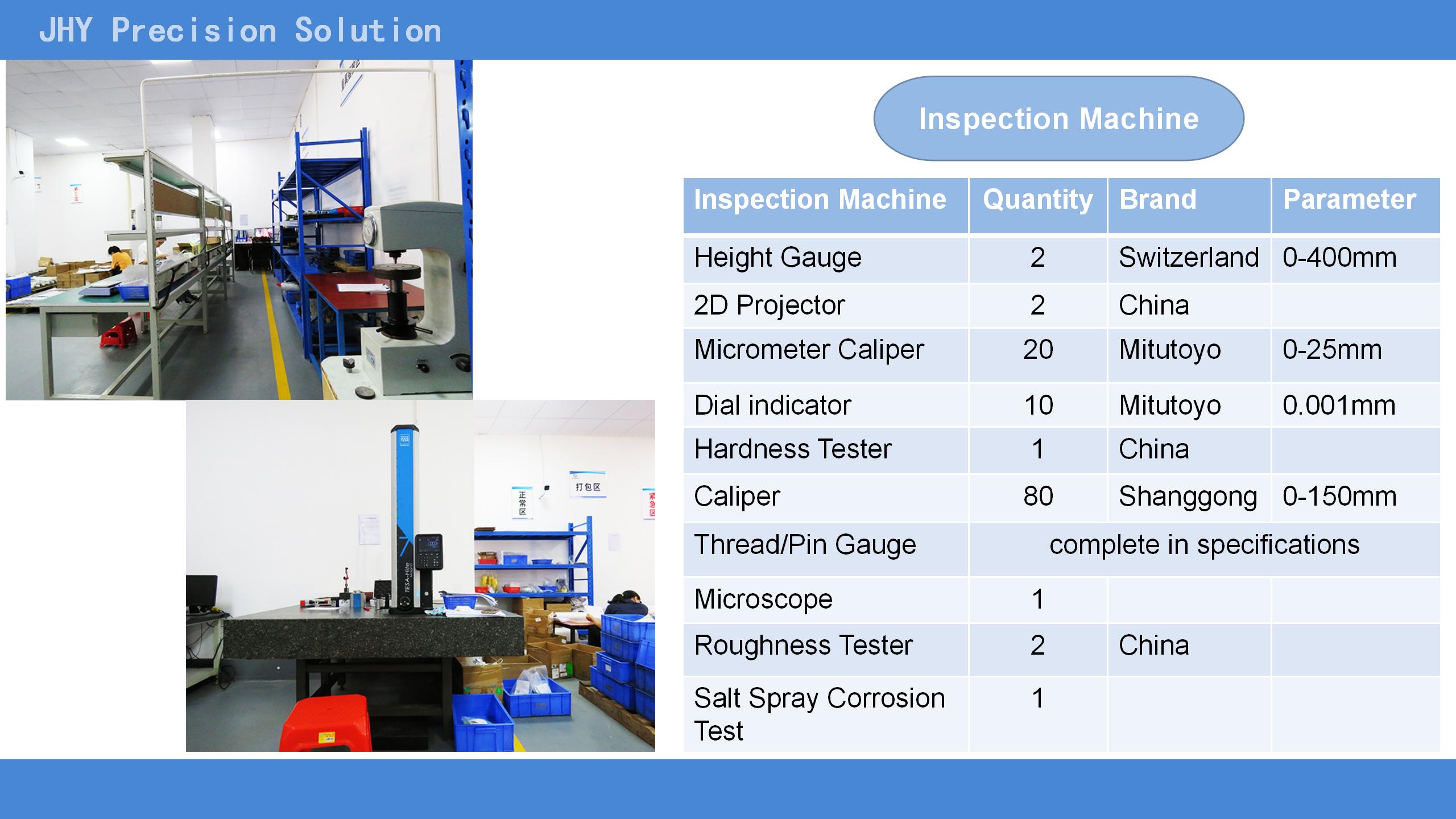

Measuring Devices :

Payment terms:

1)T/T (Telegraphic Transfer)

2)PayPal (+5% bank fees)

3)Western union

4)Cash

Delivery Terms:

DHL, FEDEX, UPS, TNT, Aramex, EMS, Post parcel, By sea, By air…

For CNC machining service pls contact :Ms Joey

Phone/WhatsApp: 0086-13352938262

E-mail: sales1@sz-jhyco.com

Contact: Will Chen

Phone: 0086-13352938262

E-mail: info@sz-jhyco.com

Whatsapp:0086-13352938262

Add: No.99 ,Brigitte Road,BaoLong,Shenzhen,China 518116

We chat